Seattle Center Monorail 2010 - a Photo Essay

Page Four of Six

Another Monorail Society Exclusive!

Commentary by Russell Noe' & Kim Pedersen

All photos copyright The Monorail Society

Kim: For the first time since the system was built, the entire route is getting all new 700 VDE power rails. The mounting brackets are the same, but were all taken off the track and refurbished.

Russ: New insulators, rails, and rails joints are being installed system-wide. We hope this will improve the operating life of the custom-manufactured carbon collector shoes that ride along the rails at 40+ mph. The old rails have visible wear in them, and are no longer aligned to the beam per original specifications.

Kim: This is about as basic a track inspection/maintenance vehicle that can be made.

Russ: We kindly call it The Cadillac. The tent is an add-on during the winter rail replacement project. Our small and even more bare-bones inspection vehicle is referred to as the Chevy (or Bentley, depending on who is talking.)

Kim: We had a chance to talk with some of the folks hired to make the project happen.

Russ: Meet Restoration Project Manager Dr. Eno Yliniemi. She received her PhD in Mechanical Engineering at the University of Washington, here in Seattle. Eno has managed these restorations brilliantly, especially considering the prototype nature of the work. She is truly one of the few World Experts on ALWEG Monorails, and has earned all of the praise we can give her! I wonder what other magic she will work in her future.

Kim: In over twenty years of exploring the world’s monorails, this was Carol’s first behind-the-scenes tour of any monorail. Here she is with Russ next to the art deco lines of the Red Train.

Russ: Yes, we will polish those Art-Deco aluminum panels before putting Red Train back into service!

Kim: The team rebuilding the system has to be able to improve, and in this case, replace all sorts of parts. Here is some corrugated aluminum for the lower skirt side panels.

Russ: These panels are custom-made by a local sheet metal company that usually rebuilds fishing boats! We have tried to bring all such contract work back home to Seattle businesses. The local response had been outstanding!

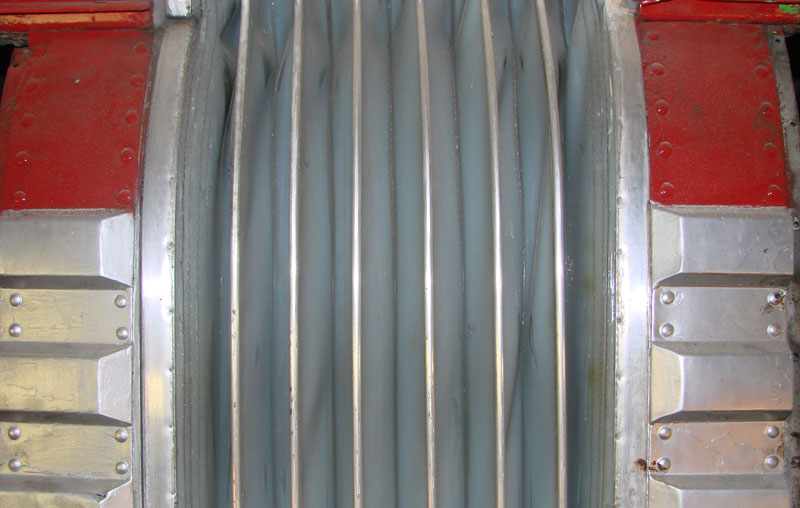

Kim: Those familiar with my photography know I like to throw in an occasional ‘art shot.’ Here you go; bellows connecting cars.

Russ: I hope I NEVER have to replace those, during my work on the Monorails!

Kim: ALWEG built the monorail for the Century 21 Seattle World’s Fair. It was to be the company’s last trains. At the time it wasn’t known if it would stay in place beyond a few years or not. As a result, no special facilities for maintenance were provided. All maintenance has to be done ‘on-beam’ in very tight spaces in the station.

Russ: Also note the two new power rails visible against the beam. They have not yet been connected to the power source to the left of this picture.

Kim: Most ALWEG-type monorails in the world have some sort of drop-out track for access to the bogies. Others have trains that are lifted completely off the bogies. No such luck in Seattle, so claustrophobics like me need not apply. Two fellows here are working in tight spaces on this bogie. Tires have been removed and the train is resting on blocks.

Russ: All 8 bogies under each train were completely rebuild: paint stripped, repainted with correct “fire-proof” paints, magna-flux tested for cracks, weld-repairs made and documented, all mounting holes re-bushed, and some line-bored where required. Whew! The bogies’ original German design and manufacture have proven to be brilliant, and will continue in service for decades.

NEXT >>>

Seattle Center Monorail 2010 - Photo Essay page One / Two / Three / Four / Five / Six

/ back to the Special Features Page / back to the Special Features Page |