|

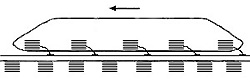

High-Speed Monorail Propulsion Recent developments in Linear Induction Motor (LIM) technology has CIFGA using the SERAPHIM, which stands for SEgmented RAil PHased Induction Motor that was developed at Sandia National Laboratories. With this motor, speeds of up to 250 mph (400km/h.) can be achieved. LIMs have been around for some time. The Tomorrowland Transit Authority people-mover at Walt Disney World is powered by LIMs, as is the Vancouver Sky Train elevated light rail system. The senatorial transit system in Washington DC, and many roller coasters and baggage handling systems, are also powered by LIMs. LIMs were used to propel test trains at speeds up to 250 mph at the Transportation Technology Center, Colorado, in the 1970s. The latest incarnation of the SERAPHIM is a single-sided design in which the aluminum plate is replaced by a shorted coil similar to the drive coil on the vehicle. The coils in the guideway are about 1m in diameter. The "air gap" between the vehicle and the guideway is about 3 cm for optimum performance. This is a large gap compared with conventional LIMs and LSMs, and is particularly useful for a high-speed vehicle. This latest application of LIM technology is called the Maglift Monorail. It is called Maglift because the SERAPHIM LIM actually generates a vertical lifting force as well as a horizontal propulsion force. Think of it as a poor man's MAGLEV-most of the benefits, very little of the costs. This technology is under consideration for the Colorado high speed corridor.

There will be three sets of brakes. The main brakes are the LIM itself which is put into reverse. The emergency brakes govern the main performance characteristics (headways, etc.). If the monorail is going full speed, fully loaded, down the maximum 8% grade and the power fails.... what then? The emergency brakes will be pneumatic with opposed surfaces that grip like a car's disk brake but directly onto the guideway steel rails (most probably the guidance rails). The advantages of this arrangement are twofold: the brakes can operate despite the power outage, and because the braking surfaces are opposed, a tremendous force can be applied and is not limited by the weight of the vehicle which is the situation with the brakes on a conventional train. The main design issue is heat dissipation. The third set of brakes are conventional disk brakes for braking smoothly to a stop at a station (used below 5 MPH). For a complete technical paper on SERAPHIM, please see The Pulsed Linear Induction Motor Concept for High Speed Trains paper (pdf) from the Sandia National Laboratories Technical Library.

|