Seattle Center Monorail 2010 - a Photo Essay

Page Five of Six

Another Monorail Society Exclusive!

Commentary by Russell Noe' & Kim Pedersen

All photos copyright The Monorail Society

Kim: The Seattle Center Monorail featured the most advanced ALWEG bogie design at the time, later reverse engineered and adopted by Malaysia’s Scomi. Four rollers are attached to corners of the bogie top, while a central pivot point is attached to the car directly above the load-bearing tire. The curved section seen to the left arches up over the tire to that pivot point.

Russ: The corner rollers are a new version referred to as “Ederer Bearings” after the local crane company that designed and fabricated them. The upper hardened roller plates were all refurbished after this photo was taken, and include shims to correct bent upper car-body frames, caused by past “incidents.” This should cause load tires to last longer, due to more even alignment and wear.

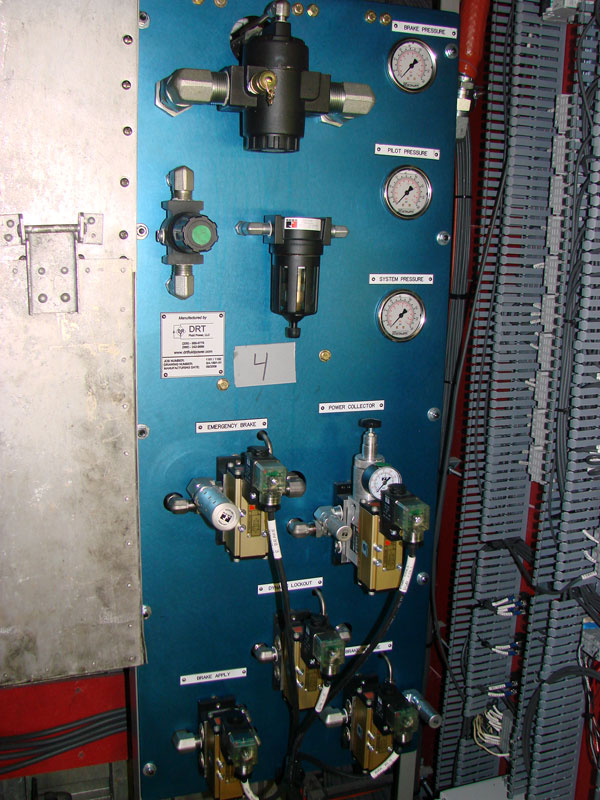

Kim: OK Russ, now we’re getting into the details where I’m lost. Help me out here, what are we looking at?

Russ: We are looking at the new air-brake panel (blue), and low-Voltage control wiring, relays, and circuit breakers, grey, on the bulkhead. In the white box below is a PLC (Programmed Logic Controller), one of 16 that controls functions on each 4-car Monorail Train. The compartment behind them contains the old-style control resistors, for the DC traction motors. No analog controls here! Someday, these will be replaced with modern AC-drive controls, the size of a shoebox!

Kim: This looks new.

Russ: The blue-anodized panel is the pneumatic brake panel. There is one per car. These panels are a new brake design that replaced the old, rusted, worn out Westinghouse transit design from 1961. All tubing throughout the trains is now stainless steel, and the panel valves are stock off-the-shelf industrial valves and regulators found in heavy industrial operations. They are simple to troubleshoot and replace, although we have never had to touch them, since installation in Blue Train!

Kim: I remember this part produces a lot of heat and produces occasional blue plasma ‘flame’ out the side of the train.

Russ: You are looking at half of the old General Electric “Control Package.” These are still rarely found on some subway/traction vehicles on the New York and Chicago transit systems, and perhaps elsewhere. There are two control packages per 4 traction motors, therefore two Packages on each Monorail. The cam shaft has 28 positions which control over 100 switches, both for high-Voltage traction control, and low-Voltage logic functions. This entire Package today would be replaced by shoebox-sized variable Voltage and Frequency device, to drive AC motors. Someday… You can imagine the maintenance required to keep these rare systems operating correctly! Our three mechanics/technicians are truly experts on these systems.

Kim: Up close and personal with a collector resting on brand new power rails.

Russ: This negative collector rides on the upper rail. The positive collector is held up against the bottom rail by a pneumatic cylinder. This allows the collectors to be dropped remotely (from the drivers’ cabs) when required.

Kim: Time to go up top and see what’s happening with the passenger compartment of the Red Train. Who are you texting Russ?

Russ: Red Train’s interior is also being refurbished to like-new condition, including replacing most of the old window gaskets. The last time Red Train operated in the rain, is did not stay dry inside!

Kim: Just like the Blue Train, the Red Train is getting a complete makeover.

Russ: Some future project will also refurbish the passenger doors. The old mechanisms remain a maintenance challenge for us.

NEXT >>>

Seattle Center Monorail 2010 - Photo Essay page One / Two / Three / Four / Five / Six

/ back to the Special Features Page / back to the Special Features Page |